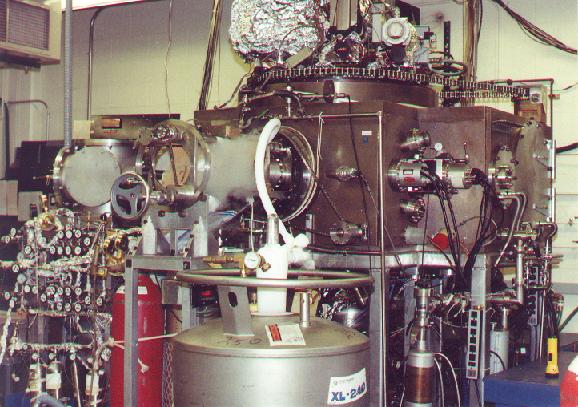

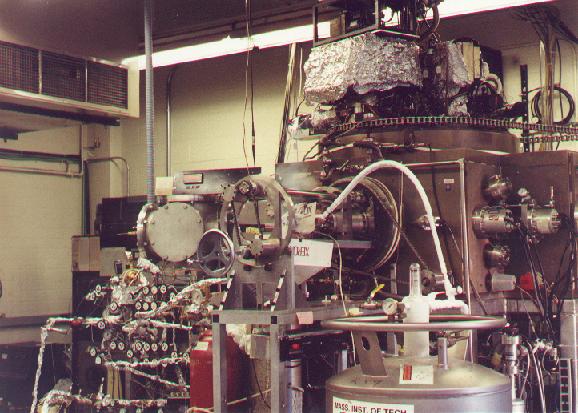

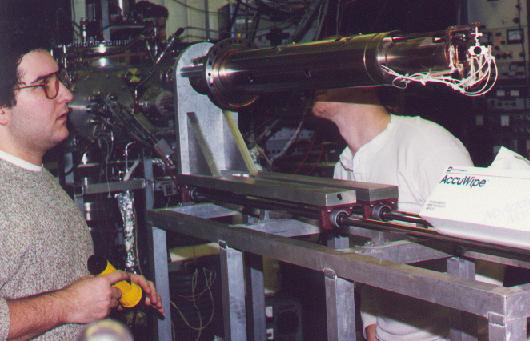

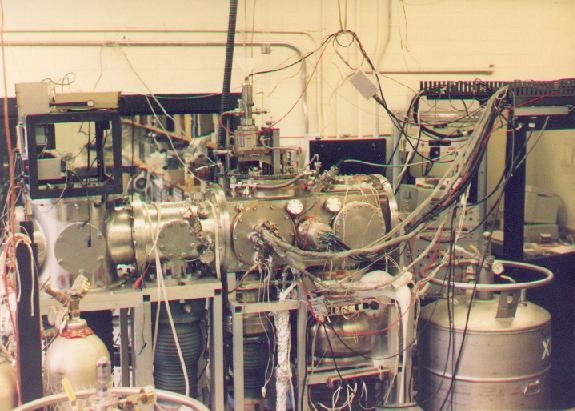

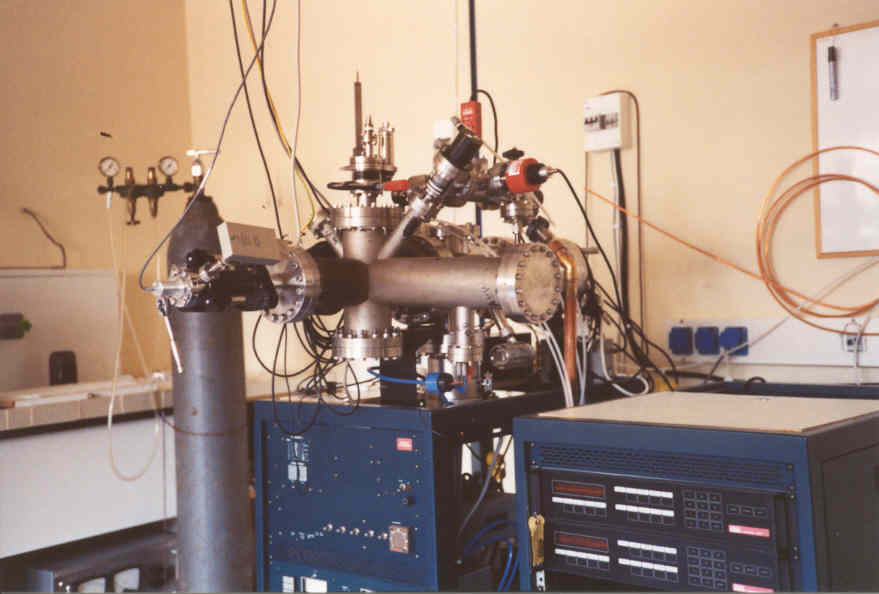

Crossed beam machine in the Zare Lab at Stanford University (above and below).

Crossed beam machine in the Zare Lab at Stanford University (above and below).

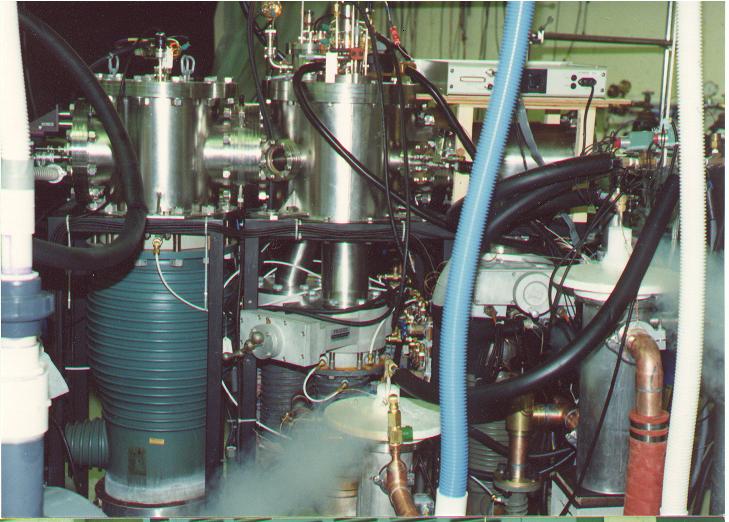

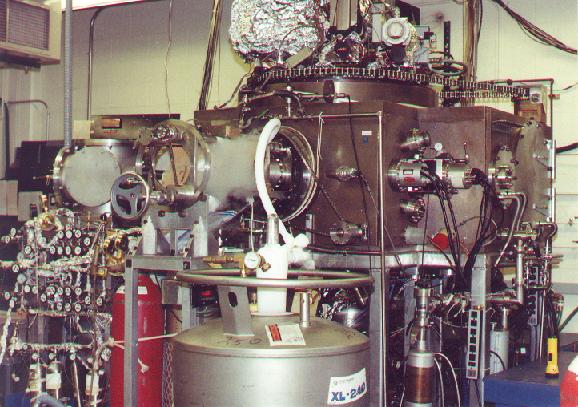

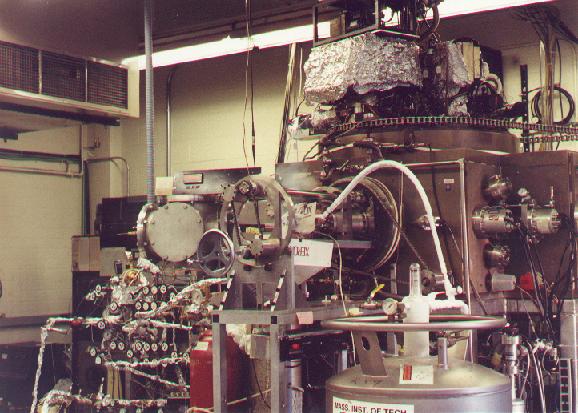

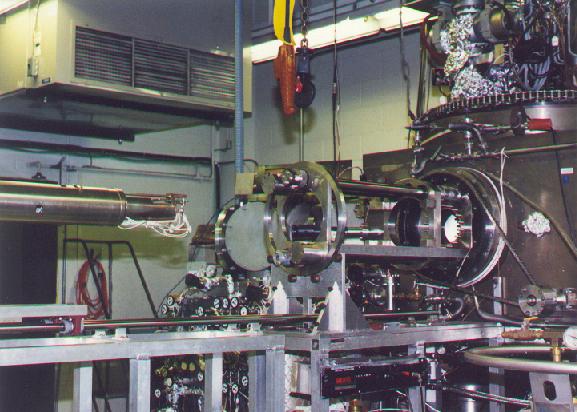

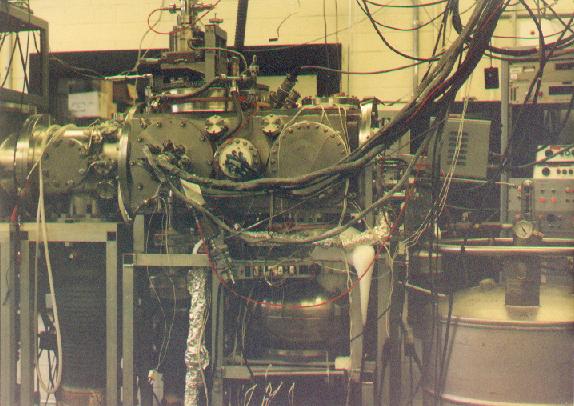

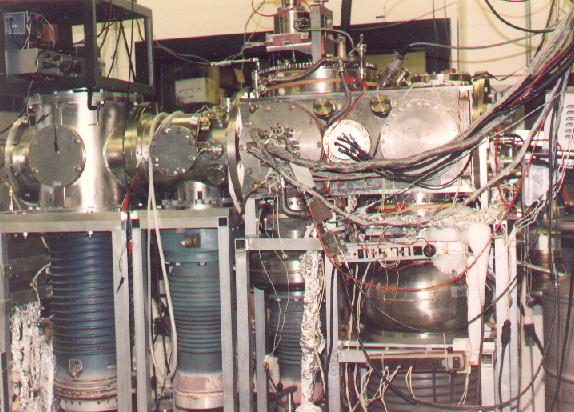

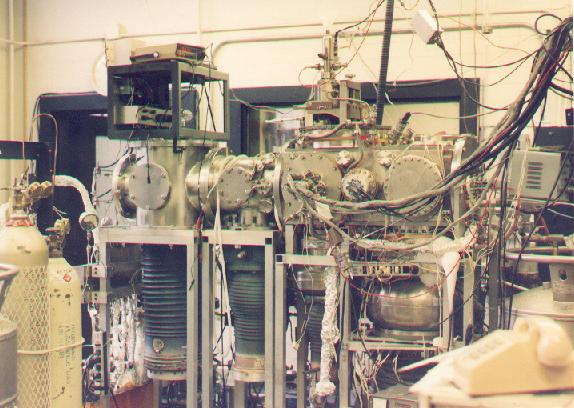

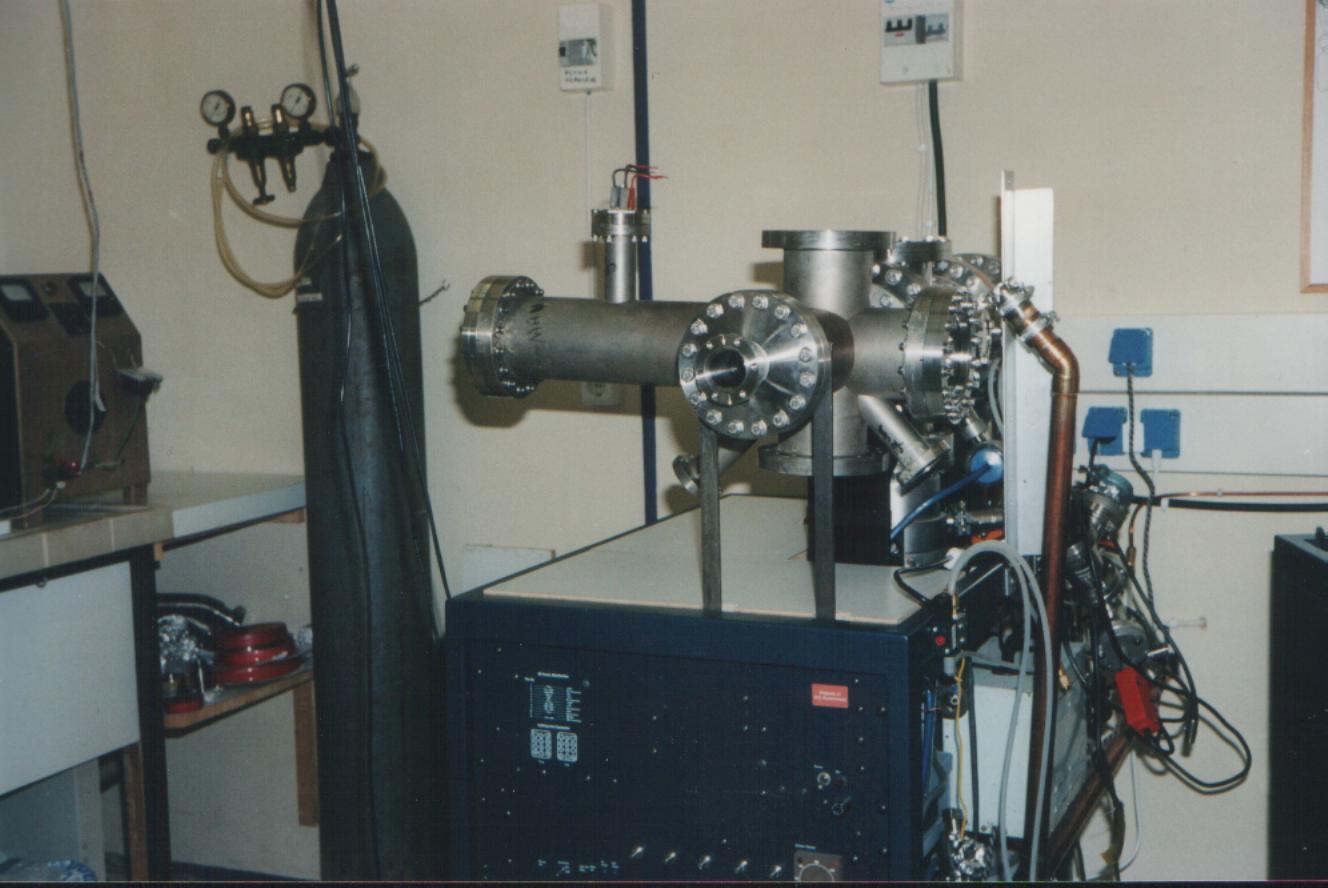

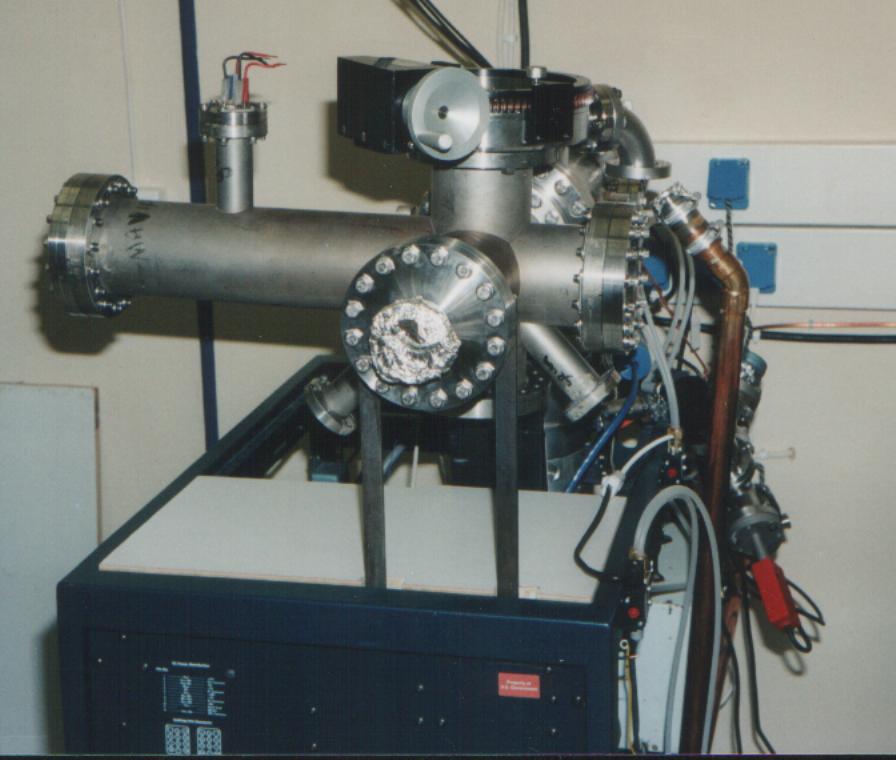

Views of the double beam, scattering chamber with a rotatable mass spectrometer ("Big machine") in the Ceyer Lab at MIT.

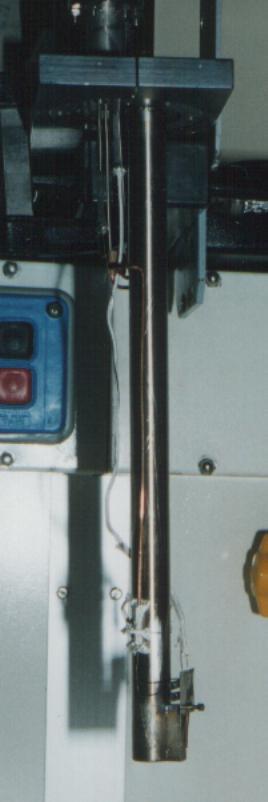

Maintenance often requires pulling the machine apart. Here the Si crystal manipulator has been loaded on a special rack and drawn out of the chamber ...

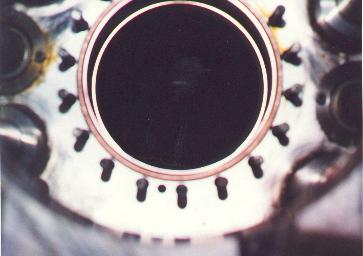

... through this hole.

Fine design allows complex control of the silicon wafer providing spatial and temperature adjustments.

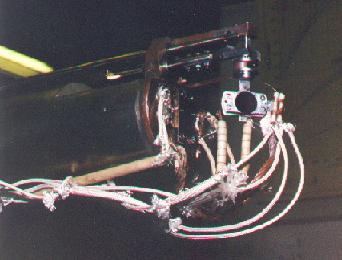

The mass spectrometer occasionally has to be repaired on the bench.

When you don't trust others to clean your vacuum components, you have to improvise your own vacuum degreaser in a fume hood, as seen in these two pictures.

Final inspection of the crystal mount by David Gosalvez (left) and Ted Trautman before reassembly.

Even a postdoc (like Yu Lin Li in 1992) has to fill the liquid nitrogen reservoir to keep the mass spectrometer detector cold.

A flange within a flange might be needed to connect a liquid nitrogen reservoir to the detector itself.

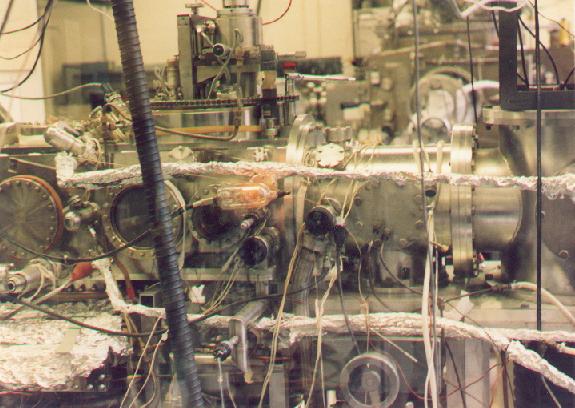

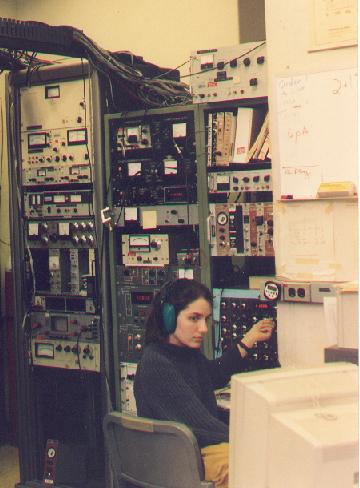

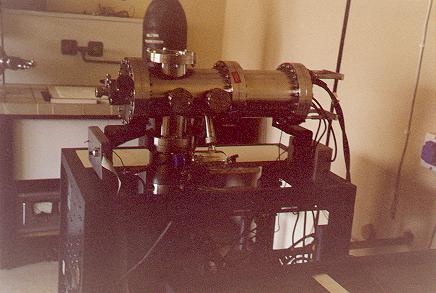

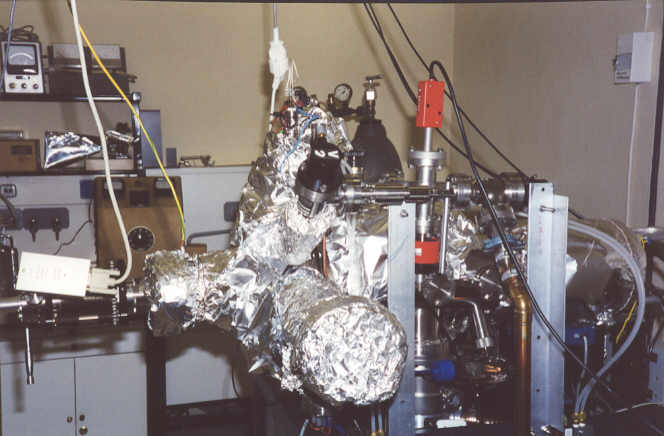

Life with UHV systems means that you have to live with your nearest neighbor's own system. To wit, views of the "Little Machine" in the Ceyer Lab at MIT.

where the greatest fun was tuning the EELS spectrometer

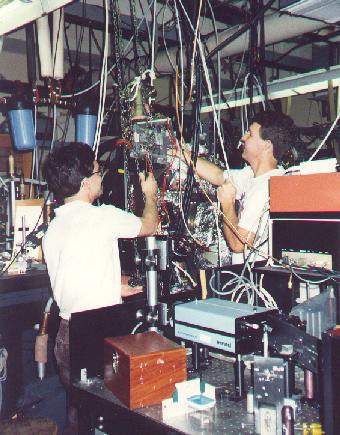

Building and maintaining also requires disassempling UHV systems,

e.g., assisting Mark Ellison in driving for the last time the Winnebego in the Zare Lab.

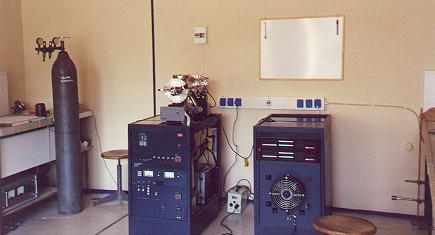

Views from the lab at the University of Athens

View of the lab (August 2000).

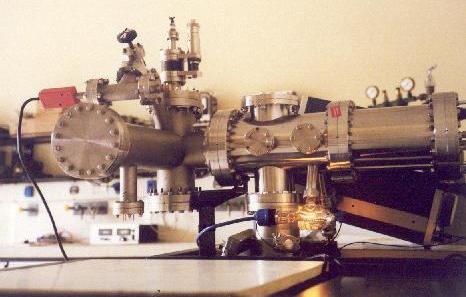

The mass spectrometer chamber (August 2000).

Kelvin probe on the shelf (August 2000).

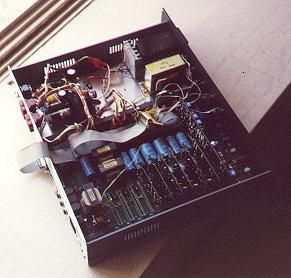

Modified mass spectrometer ionizer control (August 2000).

The electronics bench (August 2000).

Cross chamber with primitive sample manipulator (front view) (November 2000).

Cross chamber and mass spectrometer (side view) (November 2000).

Cross chamber with Kelvin probe attached (July 2001).

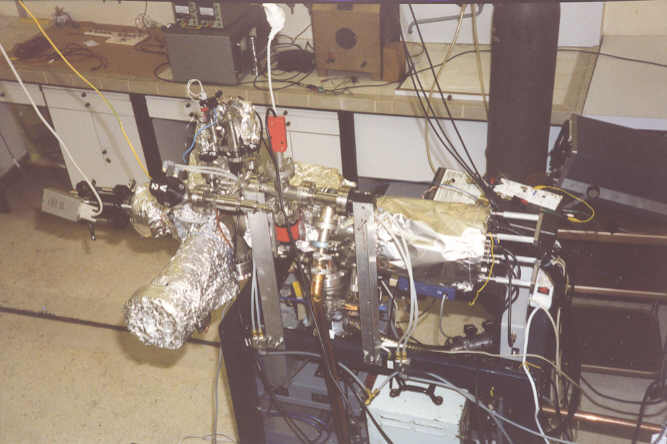

Bakeout time - side view with modified gas handling lines (December 2002).

Bakeout - aerial side view (December 2002).

Lab overview (December 2002).

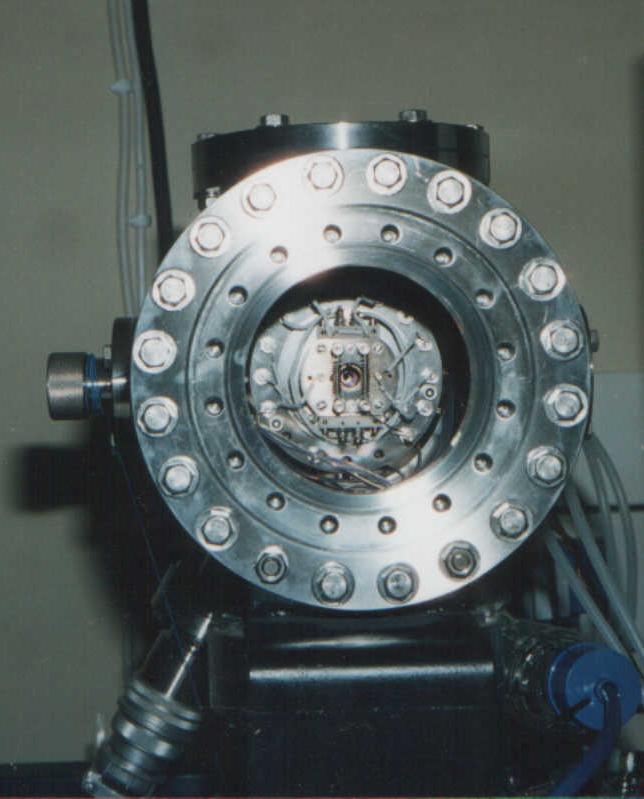

View of the ionizer region of the mass spectrometer (December 2003)

Sample holder with LN2 attached to the bench for modifications (December 2003)

Sample holder with LN2 attached to the bench for modifications (December 2003)

View of the chamber after inverting the triple cross (December 2003)

View of the chamber after attaching the rotary flange at the top of the chamber for sample manipulation (December 2003)